Hot Forging Press

- Home

- /

- Our Products

- /

- Hot Forging Press

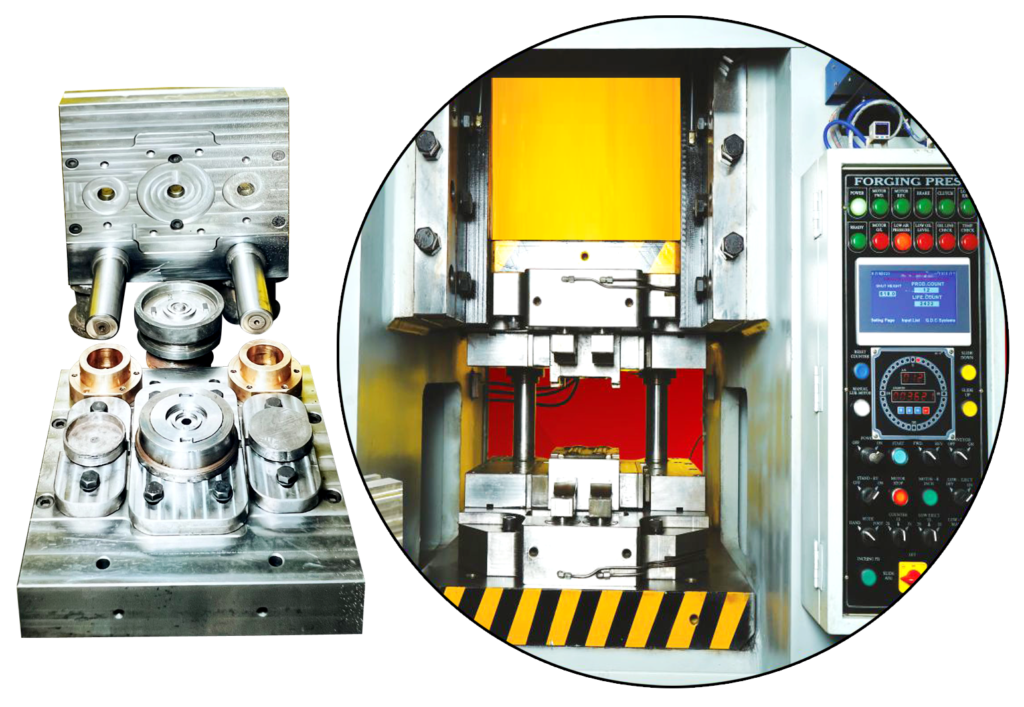

Hot Forging Press works on principle of slowly applying pressure on workpiece for a specified period of time with help of required dies. It is used for providing various shapes to sheet metal for different industrial sectors including automotive, utensils manufacturing, and architectural. This press is also provided with easy temperature setting required according to type and thickness of metal. Hot Forging Press works on smart software based control panel to assure its high effectiveness and user friendly nature.

Our Products Range

Features:

Keeps structural integrity of workpiece intact

Quick & reliable working

- Low maintenance

Technical specification for Hot Forging Press

| Model | UNITS | RHF–300 | RHF–400 | RHF–600 | RHF–800 | RHF–1000 | RHF–1300 |

| CAPACITY | TONS | 300 | 400 | 600 | 800 | 1000 | 1300 |

| Tonnage Rating Point | MM. | 3 | 3 | 5 | 5 | 5 | 5 |

| Stroke Length | MM. | 140 | 160 | 200 | 250 | 300 | 325 |

| Stroke Per Minute | S.P.M | 110 | 110 | 100 | 90 | 90 | 90 |

| Shut Height | MM. | 460 | 530 | 550 | 650 | 650 | 750 |

| Adjustment of Ram | MM. | 8 | 8 | 8 | 8 | 10 | 10 |

| Bolster Area (LR XFB) | MM. | 600×620 | 850×850 | 880×880 | 980×1000 | 1100×1050 | 1150×1150 |

| Slide Area (LRXFB) | MM. | 570×570 | 650×615 | 700×660 | 800×790 | 940×800 | 1000×1000 |

| Side Opening (WXH) | MM. | 300×450 | 450×450 | 500×500 | 500×600 | 500×600 | 500×650 |

| Main Motor | KW/HP | 22/30 | 30/40 | 37/50 | 55/75 | 75/100 | 100/125 |

| Adjustment Motor | KWXP | 0.5 | 0.75 | 0.75 | 1.5 | 1.5 | 1.5 |

| Air Pressure | KG./CM2 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 |

| Upper Ejector Type | MECH. | MECH. | MECH. | MECH. | MECH. | MECH. | MECH. |

| 1.Capacity | TONS | 1 | 1 | 2 | 2 | 3 | 3 |

| 2. Stroke | MM. | 20 | 20 | 20 | 30 | 30 | 40 |

| 3.Pin Dia | MM. | 40 | 50 | 50 | 60 | 65 | 70 |

| Lower Ejector Type | AIR. | AIR. | AIR. | AIR. | AIR. | AIR. | AIR. |

| 1.Capacity | TONS | 3 | 4 | 6 | 6 | 7.5 | 7.5 |

| 2. Stroke | MM. | 20 | 20 | 20 | 30 | 30 | 40 |

| 3.Pin Dia | MM. | 40 | 50 | 50 | 50 | 50 | 50 |

| Approx WT | TONS | 15 | 30 | 40 | 55 | 70 | 90 |